Construction Personal Protective Equipment: What You Must Know

by SafetyOutfit · Published · Updated

Personal Protective Equipment (PPE) for Construction: What You Must Know.

The construction industry plays a crucial role in shaping our world, from developing land and buildings to constructing vital infrastructures. It’s one of the largest employers globally, making up about 7% of the global workforce. But with great responsibility comes significant risk—construction is considered one of the most hazardous industries, contributing to 30-40% of workplace fatalities. As someone working in construction, whether you’re a seasoned field engineer, a safety expert, or just starting as an intern, you know the dangers that come with the job. But did you know that by strictly adhering to safety guidelines and using personal protective equipment (PPE), you can significantly reduce these risks? According to OSHA (Occupational Safety and Health Administration), proper use of PPE, along with engineering and administrative controls, is key to flattening the hazard curve in construction zones.

Some of the Personal Protective Equipment used in the construction industry

What is a Personal Protective Equipment ?

Personal protective equipment (PPE) is used to reduce employee exposure to hazards when engineering and administrative controls are not feasible or effective in reducing these exposures to acceptable levels. PPE is required wherever and whenever environment hazards, chemical hazards, radiological hazards, mechanical irritants, hazards of processes are capable of causing injury by being absorbed, inhaled, or physically contacted.

Why is PPE Important ?

Construction sites are full of hazards that can impact not only your performance but also the overall productivity of your company. Injuries can lead to labor shortages and costly workers’ compensation claims. But here’s the good news: using PPE can help prevent these issues and protect you from serious injuries or even disability.

Who pays for PPE ?

OSHA mandates that employers must provide and pay for PPE to comply with safety standards. Here’s a list of essential PPE every construction worker should have:

- Metatarsal Foot Protection: Shields your feet from heavy impacts.

- Rubber Boots with Steel Toes: Essential for working in wet or hazardous environments.

- Non-Prescription Eye Protection: Keeps your eyes safe from dust, debris, and chemicals.

- Prescription Eyewear Inserts/Lenses for Full Face Respirators: Ensures clear vision while using respirators.

- Goggles and Face Shields: Offers protection against splashes and flying particles.

- Fire Fighting PPE: Critical for those dealing with fire hazards.

- Hard Hats: A must for protecting your head from falling objects and impacts.

- Hearing Protection: Safeguards your hearing in noisy environments.

- Welding PPE: Specialized protection for those handling welding tasks.

Personal Protective Equipment for Construction

The various categories of PPE are:

A. The Face and Eye Protection

Did you know that an estimated 1,000 eye injuries occur in American workplaces every day? The financial impact is staggering, and the personal toll is even greater. According to the Bureau of Labor Statistics (BLS), about 3 out of every 5 workers injured weren’t wearing eye protection at the time of the accident. Construction workers, in particular, are at high risk, with more than 20% of all workplace eye injuries happening on construction sites. Eye injuries are preventable. By consistently wearing effective eye protection, receiving proper training, and maintaining your protective gear, you can significantly reduce the risk of injury. Here’s a quick guide to the types of face and eye protection you should be using:

1. Safety eyeglasses – Essential for tasks like carpentry, woodworking, grinding, and scaling. They are available in prescription form for those who need corrective lenses, ensuring you don’t have to compromise vision for safety.

Safety Eyeglasses

2. Safety Goggles – These can be worn over corrective lenses and offer robust protection from sparks, scaling, splashing metals, and harmful light rays. They are a must for tasks that involve potential eye hazards.

Safety Goggles

3. Face Shields – When the entire face needs protection, face shields are your go-to. They protect against flying particles, metal sparks, and chemical or biological splashes—ideal for operations with high-risk exposures.

Face Shield

4. Welding shields – Specifically designed for welding, soldering, or cutting operations, welding shields protect against infrared and radiant light burns, flying sparks, metal spatter, and slag chips. These shields are crucial for anyone involved in welding tasks.

Welding Shield

Ever wonder why it gets hard to think straight or feel dizzy in certain work environments? It could be that the air you’re breathing isn’t safe. When the oxygen levels drop below 19.5% by volume, the air becomes oxygen deficient, leading to serious health risks like impaired thinking, loss of coordination, unconsciousness, and even death. In construction, where harmful dust, fumes, mists, gases, and vapors are common, the risk of respiratory diseases like black lung, silicosis, and asbestosis is real.

To keep you safe on the job, it’s crucial to use the correct respirator for your environment. In oxygen-deficient areas, only a National Institute for Occupational Safety and Health (NIOSH)- certified respirator will do the job. These respirators are designed specifically for low-oxygen environments and shouldn’t be swapped out for other types. When dealing with poisonous gases or vapors, air-purifying respirators are your best defense. Make sure you’re using the right type to protect yourself from inhaling anything toxic.

Air-Purifying Respirator

If your work involves materials like concrete, brick, tile, or mortar that contain crystalline silica, it’s even more important to be careful. For most tasks, a respirator with N, R, or P95 filters should be your go-to. But for more intensive jobs—like cutting concrete, sandblasting, or mixing concrete—you’ll need a higher level of protection, such as N, R, or P100 filters. And if odors are an issue, filters with a charcoal layer can help keep the air you breathe more pleasant. In the construction industry, your lungs are on the front line. Protecting them isn’t just about compliance—it’s about making sure you go home safe and healthy every day. So, always use the right respirator for the job, and don’t take shortcuts when it comes to your safety gear.

Respirator with N95 Filter

C. Head Protection

When working in construction, protecting your head is a top priority. Whether it’s from falling objects or potential contact with electrical hazards, selecting the right head protection can mean the difference between a close call and a serious injury. Here’s what you need to know to choose the best helmet for the job:

a) Impact Type Helmets

Type I Helmets: These helmets are designed to protect only the top of your head from impacts. If your main concern is objects falling from above, this type of helmet is your go-to.

Type II Helmets: Offering more comprehensive protection, these helmets safeguard both the top and sides of your head, making them ideal for environments where impacts could come from any direction.

Hard Hat

b) Bump Caps

Bump Caps (Skull Guards): Bump caps are great for protecting against minor bumps and scalp lacerations from sharp objects. However, they’re not a substitute for full safety helmets since they don’t protect against impact forces or falling objects.

Skull Cap

c) Electrical Classes of Helmet

Class G Helmets (General): These helmets are designed to reduce the risk of contact with low voltage conductors up to 2,200 volts.

Class E Helmets (Electrical): If you’re working around high voltage conductors, this helmet class offers protection against exposures up to 20,000 volts.

Class C Helmets (Conductive): These helmets are not intended to provide protection against electrical hazards, so don’t use them if there’s any risk of electrical contact.

Hard hat color code

Different Colors of Hard Hat

On a construction site, the color of your hard hat is not just for looks—it signifies your role and responsibilities:

White Hard hats – Worn by site managers, engineers, foremen, and supervisors—those with experience and authority.

Yellow Hard hats – Typically worn by general laborers and earth-moving operators.

Blue Hard hats – The choice for carpenters and technical operators.

Green Hard hats – Designated for lifting operatives, signalers, and crane operators.

Orange Hard hats – Orange Hard hats are worn by lifting operatives, signalers, crane operators at a construction site

Red Hard hats – Reserved for fire marshals.

Brown Hard hats – Used by welders.

Grey Hard hats – Commonly worn by site visitors.

OSHA provides the standards for hard hat usage, but it’s also important to check with the manufacturer for specific guidelines on how often your hard hat should be replaced. Regular inspection and maintenance can ensure your helmet offers the maximum protection when you need it most.

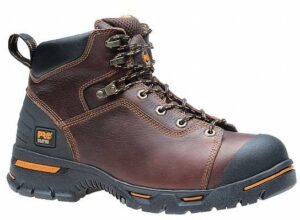

Every construction worker knows that the job site is full of potential hazards, especially when it comes to your feet. Falling or rolling objects, sharp materials that can pierce your sole, and electrical hazards are just a few of the dangers lurking around. That’s why wearing protective footwear, like safety boots, is a must.

Why Safety Footwear Matters:

Impact and Compression Protection: Keeps your feet safe from heavy objects and machinery.

Temperature Insulation: Protects against extreme heat or cold.

Slip Resistance: Helps prevent slips and falls on slick surfaces.

Chemical and Electrical Hazard Protection: Shields your feet from harmful substances and electrical shocks.

Protective Footwear

Handling materials on a construction site can expose your hands to all kinds of hazards—cuts, abrasions, punctures, burns, and even extreme temperatures. Choosing the right gloves is crucial to protect your hands while working.

Type of Gloves to Consider:

Leather Gloves: Great for general material handling and protection against rough surfaces.

Welder’s Gloves: Essential for welders, providing heat resistance and protection from sparks.

Aluminum-Backed Gloves: Offer added protection against heat and flames.

Insulated Gloves: Ideal for working with extreme temperatures or cold environments.

Pro Tip: Replace your gloves regularly, especially if they start to wear out or if they’re no longer providing the protection you need.

Different Types of Safety Gloves

F. Hearing Protection

Protect Your Hearing: Don’t Let Noise Steal Your Ears

One of the silent dangers of construction work is noise exposure. The damage caused by excessive noise might not be noticeable right away, but over time, it can lead to permanent hearing loss. And here’s the kicker—hearing loss can’t be cured, but it can be prevented.

When to Use Hearing Protection:

If you’re exposed to noise levels at or above 85 decibels over an eight-hour period, it’s time to protect your ears. A good hearing conservation program is a must in any noisy workplace, and PPE is your first line of defense.

Types of Hearing Protection:

Molded Earplugs: Pre-shaped and ready to use.

Custom-Molded Earplugs: Tailored to fit your ears perfectly for maximum protection.

Self-Molded Earplugs: Can be shaped to fit your ear on the spot.

Earmuffs: Provide coverage over the entire ear, blocking out the most noise.

Different Types of Hearing Protection

G. Fall Protection

Construction is one of the most hazardous industries, with falls leading the list of dangers. Even seasoned pros can lose their footing or balance in an instant. But here’s the good news—most fall-related injuries and fatalities can be prevented. How? By using the right fall protection systems. Let’s break it down.

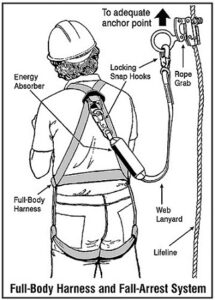

I. Personal Fall Arrest Systems (PFAS) – Your Safety Net

PFAS is designed to stop a fall in its tracks. Here’s what makes up this system:

1. Body Harness – This fits around your torso and spreads the impact forces if you fall, while still letting you move freely.

2. Body Belts – Useful for positioning but not for fall arrest—these can cause serious internal injuries if misused.

3. The Anchorage – The solid anchor point must hold at least 5,000 pounds (2268 kg) to keep you secure.

4. Lanyards – These flexible lines connect you to the anchor. Make sure they are rated to withstand 5,000 pounds (2268 kg).

5. Deceleration devices – These absorb the shock of a fall, whether it’s a shock-absorbing lanyard or a rope grab.

6. Shock-absorbing Lanyard – Shock-absorbing Lanyard reduces the impact of a worker during fall arrest by extending up to 3.5 feet to absorb the arrest force by up to 900 pounds (408 Kg).

7. Rope Grab – Rope grab allows a worker to move up a vertical lifeline but automatically engages and locks on the lifeline if the worker falls

8. Lifeline – Vertical or horizontal, these cables connect your harness to the anchor, ensuring you’re secure no matter where you are.

Components of Personal Fall Arrest Systems

II. Personal fall-restraint systems: Stopping Falls Before They Start. These systems keep you from falling in the first place:

1. Positioning-device system – The Positioning-device system positions a worker and limits a fall to 2 feet. It makes it easier to work with both hands, free on a vertical surface such as a concrete wall. It comprises of anchorage, connectors and body support

2. Guardrail system – Simple and effective, guardrails keep you from going over the edge. It consists of a top rail, mid-rail, and intermediate vertical member. It can also be combined with toe boards that prevent materials from rolling off the working/walking surface

3. Safety-net systems – If a fall happens, this system catches you. Installed just below where you are working, it is there as a last resort. It must be installed as close as practicable under the surface on which employees are working, but not more than 30 feet below. The safety must extend outward from the outermost projection of the work surface and the potential fall area must be unobstructed.

4. Warning-line system – For low-slope roofs, this system lets you know when you are nearing an edge. It can only be used for roofing works on roofs that have slopes of 2:12 or less, vertical to horizontal. The purpose of the line is to warn roofers that they are near an unprotected edge. It consists of ropes, wires, or chains and supporting stanchions.

5. Slide-guard system – Prevents you from sliding down a sloped roof—perfect for when you’re working on a steep incline. The system consists of a slide guard (2 by 6-inches lumber) and at least two roof brackets and must be installed under the supervision of a competent person

H. Protective clothing

Transportation accidents pose a major threat to construction workers on foot. Wearing the right high-visibility gear is crucial. ANSI/ISEA 107-2004 specifies four performance classes of apparel/headwear, namely:

Class E Garments – These pants and shorts need to be paired with Class 2 or 3 garments for full protection.

Class 1 Garments – Ideal for low-speed environments (under 25 mph), they help you stand out in basic conditions. They provide the minimum amount of required material needed to tell the pedestrian worker apart from the environment.

Class 2 Garments – These are your go-to for complex worksites like hurricane recovery—more visibility for more dangerous work. They provide better visibility than class 1 garments by providing additional coverage of the torso.

Class 3 Garments – Offering the highest level of visibility, these are essential when you’re exposed to high-speed traffic. Especially in situations where a pedestrian worker will be exposed to the higher vehicle speed.

Classes of Hearing Protective Clothing

Barriers made from posts and wires or boards keep you away from hazards like pits and shafts. Don’t forget other protective gear like shields, restraints, and even protective ointments.

Other personal protective equipment include Protective ointments, Shields, and Restraints

Protective Barrier

Maintenance and Repair of PPE

Your PPE is only as good as the care you give it. Regular inspection, cleaning, and proper storage will ensure it’s ready when you need it most. Always follow the manufacturer’s instructions to keep your gear in top shape.

Every employer must organize a program for maintenance of PPE and the program must include:

Inspection of PPE for defects (including a leak check);

cleaning and disinfecting;

repair; and

storage

Dress for Safety: The Right Clothing Matters

In construction, your clothing can be your first line of defense. Avoid anything too loose or too tight, as both can be hazardous. Skip the jewelry, and make sure any toxic-stained clothing is properly cleaned before you wear it again.

The Impact of the coronavirus on construction workers’ PPE

COVID-19 changed the way we live and work, and the construction industry felt the impact just like every other sector. Even now, as we continue to navigate the challenges of this pandemic, it is crucial to stay vigilant and protect ourselves on the job. The CDC has laid out clear guidelines specifically for construction workers to help minimize the risk of contracting the virus while keeping job sites running smoothly. Here’s what you need to know.

Protect Yourself with These Simple Steps

COVID-19 is still with us, so it’s important to follow these key safety practices:

A Sample of Cloth Face Covering

Wear cloth face coverings: When maintaining distance isn’t possible, face coverings are a must. They’re not a substitute for respirators where required, but they help reduce the spread of the virus in close quarters.

Maintain Social Distancing: Keep at least 6 feet between yourself and others whenever possible. It’s a simple way to reduce transmission.

Limit Tool Sharing: If you can, stick to using your own tools. When sharing is necessary, make sure everything is disinfected between uses.

Clean and Disinfect Regularly: High-touch surfaces like shared equipment and portable toilets should be cleaned and disinfected often to reduce the risk of spreading the virus.

Practice Proper Hand Hygiene: Wash your hands frequently with soap and water for at least 20 seconds. When that’s not an option, use a hand sanitizer that contains at least 60% alcohol.

Use Tissues: Always cover your mouth and nose with a tissue when you cough or sneeze, and avoid touching your face as much as possible.

Stay Home if You’re Sick: If you have any symptoms of COVID-19, notify your supervisor and stay home to prevent spreading the virus to your coworkers.

Understanding the Role of PPE in Preventing COVID-19

While cloth face coverings are important, they’re just one part of your COVID-19 defense strategy.Notify your supervisor and stay home if you have symptoms.

N.B. Cloth face coverings are different from respiratory protectors, and should not be used as an alternative where respirators are required.

Click here to learn more about the guidelines to protect construction workers from contracting the coronavirus illness.

Final Thoughts

Here’s what to keep in mind:

10 Responses

[…] rules are obeyed. Afterward, implementation of protective measures must follow such as providing personal protective equipment and technologies, compliance with equipment manuals, and employee involvement in the discussion of […]

[…] Everything You Need to Know About Your Personal Protective Equipment […]

[…] Everything You Need to Know about Your Personal Protective Equipment […]

[…] studies have shown that the use of Personal Protective Equipment (PPE) is the number one defense against safety and health risks at work. More specifically, the […]

[…] Suggested Read: Vital Personal Protective Equipment in our Workplace […]

[…] visibility clothing is a form of Personal Protective Equipment (PPE) which has reflective properties that make it easily identifiable in any condition (especially […]

[…] Protection Devices (HPD) are a form of personal protection equipment (PPE) and are considered the last option to control exposures to noise after engineering and […]

[…] use of Personal Protective Equipment (PPE) has proven to help minimize occupational hazards. Nonetheless, the utilization of a safety […]

[…] apply the use of a fall protection system to prevent falls. Nonetheless, fall prevention can also be accomplished […]

[…] Protection Devices (HPD) are a form of personal protection equipment (PPE) and are considered the last option to control exposures to noise after engineering and […]