Safety Gloves for Construction work: What You Must Know

Safety glove is a form of hand protection used in the construction industry to protect employees from job hazards that could damage their hands. There is no ANSI standard for gloves but Occupational Safety and Health Administration (OSHA) recommends that the selection should be based upon the tasks to be performed, weather conditions, the performance, and the construction characteristics of the glove material. The work activities of the employee should be studied to determine the:

degree of dexterity required

duration of the task

frequency of the task

degree of exposure to the hazard

physical stresses that will be applied

Different Types of Safety Gloves

What does safety gloves protect against ?

Construction activities involve material handling, which makes our hands susceptible to hazards like Cuts, lacerations, abrasions, punctures, thermal burns, harmful temperature extremes (heat) among others. Safety gloves will offer protection against these hazards. Additionally, More than any other part of our body, our hands are most likely to come in contact with these hazardous chemicals. Safety gloves protect employees against the toxic effects.

Types of Safety Gloves

1. Disposable gloves: Disposable gloves are usually made of light-weight plastic, it help guard against mild irritants. These gloves come in different styles (texture, color, materials) and are mostly used by Healthcare professionals. They are used for work in security, and food processing industries.

Disposable Gloves

2. Fabric gloves: Fabric gloves are made of cotton and are generally used to improve grip when handling slippery objects. They also help insulate the hand from mild heat or cold. Other pros about fabric gloves are: they offer abrasion resistance, they don’t leave scratches, they can be used in the food industry because they can be washed.

Fabric Gloves

3. Leather gloves: Leather gloves are usually made from animals’ skin (for example pigskin, cowhide, deerskin, goatskin, peccary). They offer useful grips, protection from occupational hazards protection from accidental cuts and scratches. They are commonly used by persons working with cutting tools (or other sharp instruments), electricity, and arc welding for protection against electrical shocks, heat, ultraviolet rays, and infrared rays.

Leather Gloves

4. Aluminized gloves: Aluminized gloves are made of aluminized fabric. They offer protection from high temperature and insulate hands from intense radiant heat. Aluminized gloves are used by persons working with molten materials or heat, furnace and foundry

Aluminized Gloves

Fingerless Work Gloves – Fingerless gloves resemble regular gloves except that finger columns are half-length and opened, allowing the wearers’ fingers to be shown. They protect the palm and encourage firmer grips useful where dexterity is required that normal gloves would restrict. They also help keep the hands warm.

Fingerless Gloves

6. Chemical resistance gloves: made of rubber, neoprene, polyvinyl alcohol, etc. The gloves protect hands from corrosives, oils, and solvents. The glove chart below provides a guide to the different types of glove materials and the chemicals they can be used against.

Chemical Resistance Gloves

Types of Chemical Resistance Gloves

Material Type | Pros | Cons | Function Against |

|---|---|---|---|

Natural rubber | Low cost, good physical properties, dexterity | Poor against oils, greases, organics. It may also be of poor quality | Bases, alcohols, dilute water solutions; fair against aldehydes, ketones |

Natural rubber blend | Low cost, dexterity, chemical resistance against some chemicals | Physically inferior to natural rubber | Bases, alcohols, dilute water solutions |

Polyvinyl chloride (PVC) | Low cost, good physical properties, medium cost, medium chemical resistance | Plasticizers can be stripped, it may be of poor quality | Strong acids and bases, salts and other water solutions, alcohols |

Neoprene | Medium cost, medium chemical resistance, medium physical properties | N/A | Oxidizing acids, anilines, phenol, glycol ethers |

Nitrile | Low cost, excellent physical properties, dexterity | Poor against benzene, methylene chloride, trichloroethylene, many ketones | Oil, greases, aliphatic chemicals, xylene, perchloroethylene, trichloroethane; fair against Toluene |

Butyl | Specialty glove, polar organics | Expensive, Poor against hydrocarbons, chlorinated solvents | Glycol ethers, ketones, esters |

Polyvinyl alcohol (PVA) | Specialty glove, it resists a very broad range of organics, good physical properties | Very expensive, water sensitive, poor against light alcohols | Aliphatics, aromatics, chlorinated solvents, ketones (except acetone), esters, ethers |

Fluoroelastomer (Viton) | Specialty glove, organic solvents | Extremely expensive, poor physical properties, poor against some ketones, esters, and amines | Aromatics, chlorinated solvents, also aliphatics and alcohols |

Norfoil (Silver Shield) | Excellent Chemical resistance | Poor fit, easily punctures, poor grip, stiff | Use for Hazmat work |

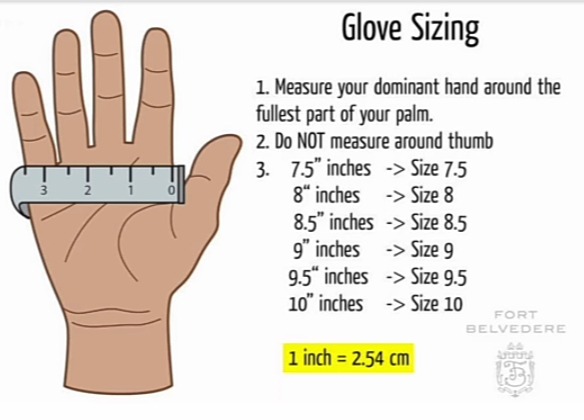

How to Measure your Glove Size

It is unsafe for a construction worker to work with a glove that gets out of hand every time because it is oversize; likewise, it is uncomfortable to work with an undersized glove, that is why It is important to get a glove that fits accurately with one’s hand by simple hand measurement and use of glove size chart. Follow these steps:

Determine what your dominant hand is (it is the right hand if you are right-handed; it is the left hand if you are left-handed)

Then you measure around the widest part of your hand (metacarpal) with a tape measure

Keep the measuring tape tight around your hand

Read and record your measurement

The glove size is the same as your measurement in inches.

For example:

if you measure 7.5 inches, then your glove size is 7.5;

if you measure 8 inches, then your glove size is 8,

if you measure 8.8 inches, then your glove size is 9,

If you measure 9.4 inches, you should go for a 9.5 glove size.

However, It is better to go down the size because the glove would stretch in the long run

if you measure 7.2 inches, then you should go for a size 7 glove.

Glove Sizing